Wir gratulieren den fünf gewählten Successful-Practice-Unternehmen und freuen uns auf die baldigen Unternehmensbesuche und den damit verbundenen Austausch!

How can development processes be digitally integrated? What degree of digitization of product development is efficient? What are the potentials and possible applications for the digital twin in development? More than ever, these are central questions in the product development of manufacturing companies. An up-to-date and holistic understanding of digital consistency in product development is therefore of major importance for the success of strategic decisions. Especially in the age of increasing digitization of products and processes, promising potentials but also challenges arise.

Therefore, we, the Laboratory for Machine Tools and Production Engineering (WZL) of RWTH Aachen University and the Complexity Management Academy, in cooperation with an industry consortium, would like to identify successful and proven best practices for the end-to-end continuity of product development. Use the benchmarking study "Digital Product Development" to examine your own approach to end-to-end continuity of product development, to gain further impulses and find out about successful approaches based on the study results.

We look forward to your participation! Please use the button on the top of the page.

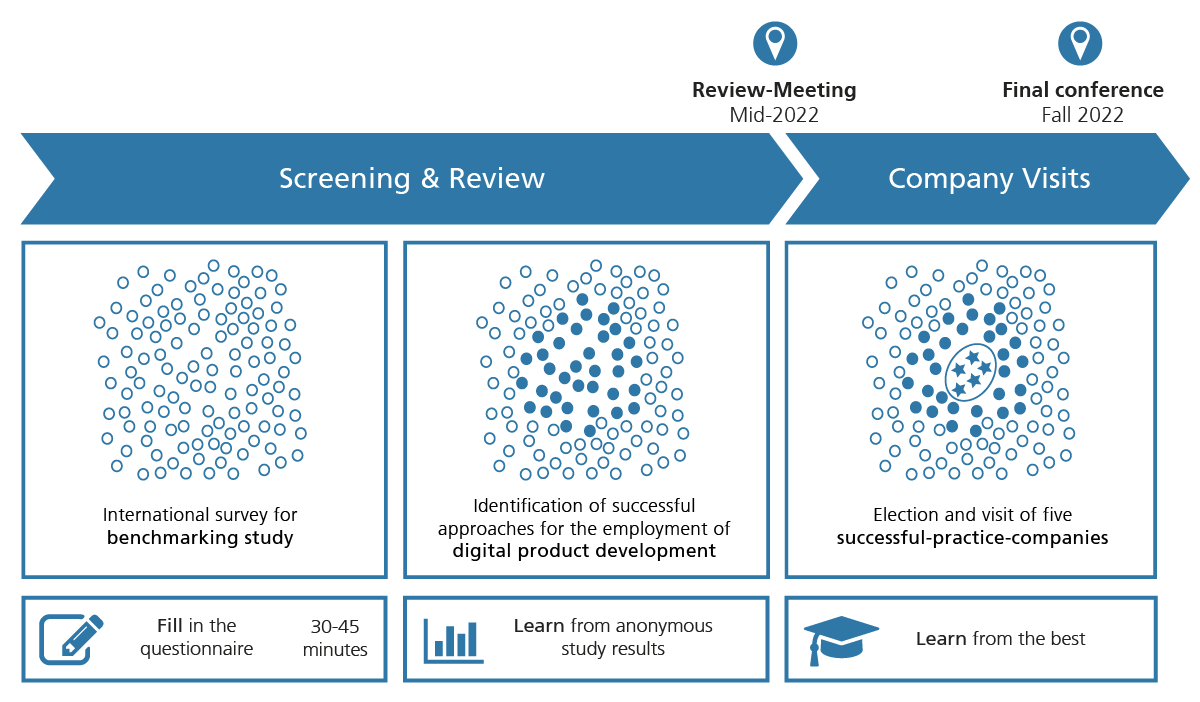

The benchmarking study is designed for approximately 10 months and starts with a screening phase, which pursues the goal of a comprehensive industry data collection based on the questionnaire. With the help of our expert network from industry and science, the returns are analyzed during the evaluation and promising approaches are detailed in depth through case studies with the corresponding study participants. In this phase, all study participants receive an evaluation of the relative positioning of their own company compared to the most successful participants in the study. Finally, five Successful Practice companies are visited by the industry consortium and the respective other Successful Practice companies under the motto "learning from the best".

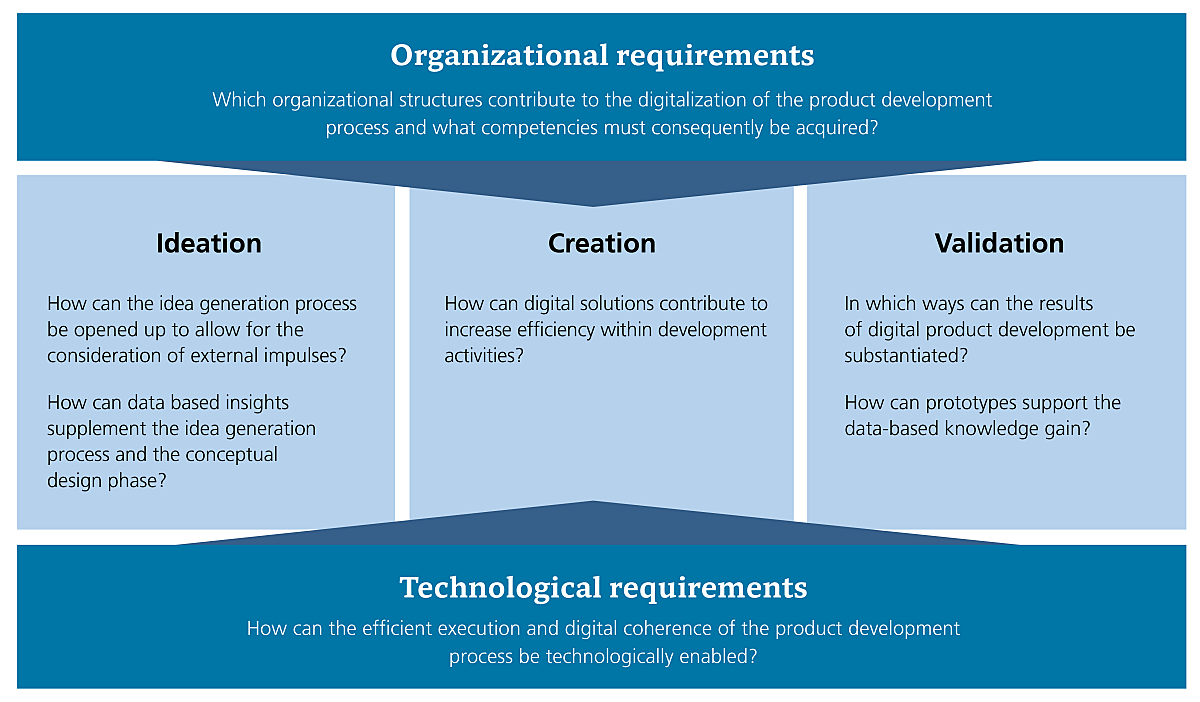

Shown below is the scope of the international benchmarking study. The areas serve to structure the topic and enable a target-oriented discussion within the project.

Benjamin Lender, M.Sc.

Project Lead

Phone: +49 (0) 241 80-28205

Mobil: +49 (0) 151 405 66681

Gereon Bönsch, M.Sc.RWTH

Project Team Member

Phone: +49 (0) 241 80-27593

Mobil: +49 (0) 151 467 74073

Dr.-Ing. Maximilian Kuhn

Chief Engineer - Department Innovation Management

Phone: +49 (0) 241 80-28196

Mobil: +49 (0) 151 431 64208

Email: m.kuhn@wzl.rwth-aachen.de